ポリイミドNEWS Polyimide NEWS

UPILEX®-NVFの特徴

2025年11月12日

2025年11月12日

PI film for laminated type CCL

Features of UPILEX

- High-strength, tear-resistant tough film

- High heat resistance and dimensional stability, with excellent workability

Comparison Chart with Other TPI Films

★☆☆: Standard、 ★★☆ : Good、 ★★★ : Excellent 、 -: Not yet rated

Film properties

| Item | Unit | 25NVF | 50NVF | 75NVF | LCP※ | 50NVT | Reference Method /Condition |

||

|---|---|---|---|---|---|---|---|---|---|

| Thickness (Nominal) | μm | 25 | 50 | 75 | 50 | 50 | − | ||

| Electrical | Dielectric constant | 10GHz | − | 3.5 | 3.5 | 3.5 | 3.4 | 3.6 | Split-Cylinder Resonator Method 25℃, 50%RH |

| Dissipation factor | − | 0.005 | 0.005 | 0.005 | 0.002 | 0.009 | |||

| Transmission loss | 6GHz | dB/100mm | -3.1 | -1.8 | -1.4 | -1.5 | -2.0 | Microstripline 25℃, 50%RH |

|

| 10GHz | -4.2 | -2.5 | -1.9 | -2.1 | -2.9 | ||||

| Mechanical | Tensile strength | MPa | 540 | 600 | 530 | 230 | 500 | ASTM D882 | |

| Elongation | % | 80 | 75 | 75 | 50 | 80 | ASTM D882 | ||

| Tensile modulus | GPa | 7.3 | 8.1 | 7.8 | 3 | 7.7 | ASTM D882 | ||

| Tear strength / trouser | N / mm | 3.3 | 5.0 | 6.4 | 5.3 | 4.9 | JIS K 7128-1 | ||

| MIT | Cycle | >100,000 | >100,000 | 41,000 | >100,000 | 29,000 | ASTM D2176 R=0.38mm,9.8N |

||

| CTE (MD) | ppm/℃ | 19 | 19 | 20 | 18 | 19 | TMA 50-200℃ |

||

| Tg (Tm) | ℃ | 270 | 270 | 270 | (335) | 280 | DMA (DSC) | ||

| Moisture absorption | % | 1.0 | 1.1 | 1.2 | ≦ 0.1 | 0.8 | 25℃, 50%RH | ||

| Light transmittance / 600nm | % | 73 | 55 | 42 | ≒0 | 64 | JIS K 7136 | ||

| Haze | % | 5 | 8 | 10 | ≒100 | 6 | JIS K 7136 | ||

UBE measured value and catalog data.

These data are measured values, not guaranteed values.

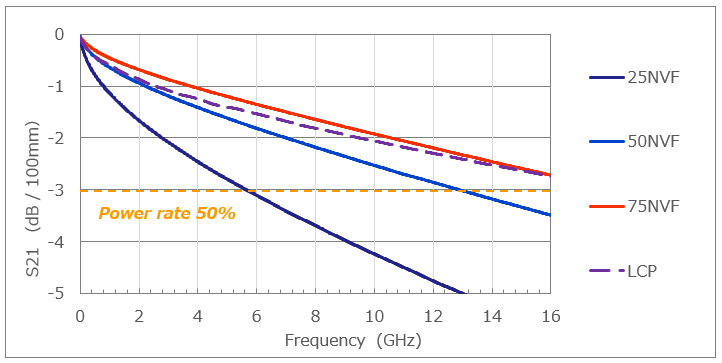

Transmission loss

75NVF is lower transmission loss than LCP and can be available in the wide range to high frequency

| Item | Unit | 25NVF | 50NVF | 75NVF | LCP | |

|---|---|---|---|---|---|---|

| Thickness | μm | 25 | 50 | 75 | 50 | |

| Transmission loss | 10GHz | dB / 100mm | -4.2 | -2.5 | -1.9 | -2.1 |

| Power rate | % | 38 | 56 | 64 | 62 | |

Transmission loss = 10 log10 (output power / input power)

Power rate = (output power / input power)×100

These data are measured values, not guaranteed values.

Mechanical properties

UPILEX®-NVF has superior mechanical properties compared to LCP

Tensile property

These data are measured values, not guaranteed values.

Dimensional stability

The Dimensional Change of UPILEX®- NVF is within 0.05% after High Temp Treatment

Conditions of CCL production

Method : Roll Laminate, Laminate temperature : 350℃, Copper foil : Rolled copper foil

These data are measured values, not guaranteed values.

Solder heat resistance

| Sample | Solder heat resistance | |||||||

|---|---|---|---|---|---|---|---|---|

| TPI | SIDE | Test Temperature [℃] | Heat resistance temperature [℃] |

|||||

| Grade | 290 | 300 | 310 | 320 | 330 | |||

| 25NVT | A | ○ | ○ | ○ | ○ | × | 320 | 320 |

| B | ○ | ○ | ○ | ○ | ○ | 330 | ||

| 50NVT | A | ○ | ○ | ○ | × | × | 310 | 300 |

| B | ○ | ○ | × | × | × | 300 | ||

| 25NVF | A | ○ | ○ | ○ | ○ | ○ | 330 | 330 |

| B | ○ | ○ | ○ | ○ | ○ | 330 | ||

| 50NVF | A | ○ | ○ | ○ | ○ | ○ | 330 | 330 |

| B | ○ | ○ | ○ | ○ | ○ | 330 | ||

| 75NVF | A | ○ | ○ | ○ | ○ | ○ | 330 | 320 |

| B | ○ | ○ | ○ | ○ | × | 320 | ||

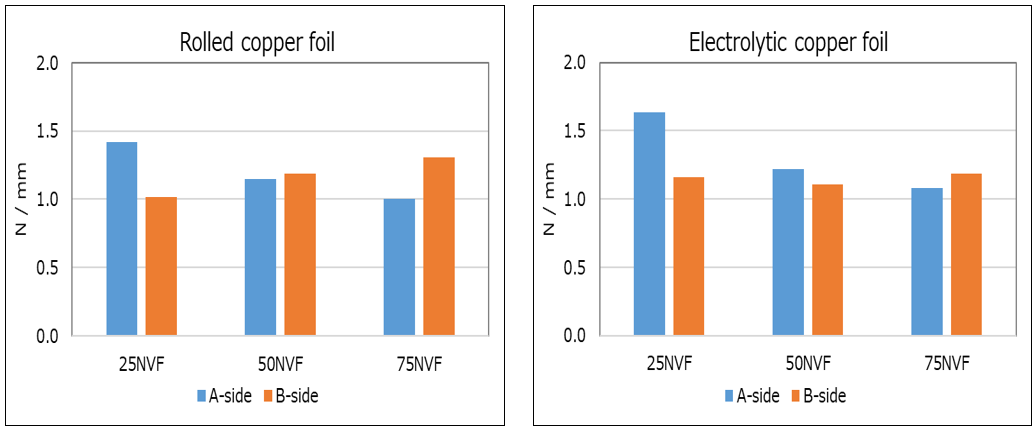

Peel Strength

The Peel Strength of UPILEX®-NVF is ≧ 1.0N/mm

Conditions of CCL production

Method : Roll Laminate, Laminate temperature : 360℃, Copper foil :Rolled copper foil / Electrolytic copper foil

These data are measured values, not guaranteed values.