Policy and Basic Mindset

UBE Group Basic Policy for Nature Positive

The UBE Group will contribute to solving global environmental problems by focusing on Carbon Neutrality, Circular Economy, and Nature Positive (conservation and reconstruction of the natural environment).

Nature Positive means halting the loss of biodiversity, which is an intrinsic property of nature, and putting nature on a path to recovery. The UBE Group's corporate activities may have an impact on nature. It is necessary to reduce this impact in our own manufacturing and value chain, and to restore degraded natural environments.

The UBE Group will contribute to the conservation and restoration of the natural environment and the sustainable use of ecosystem services by first understanding its dependence on and impact on nature in its business activities, and by identifying risks and opportunities.

Scope

This policy applies to the UBE Group (UBE Corporation and its consolidated subsidiaries) and covers the entire value chain.

Goal

Contributing to the realization of Nature Positive

Commitment

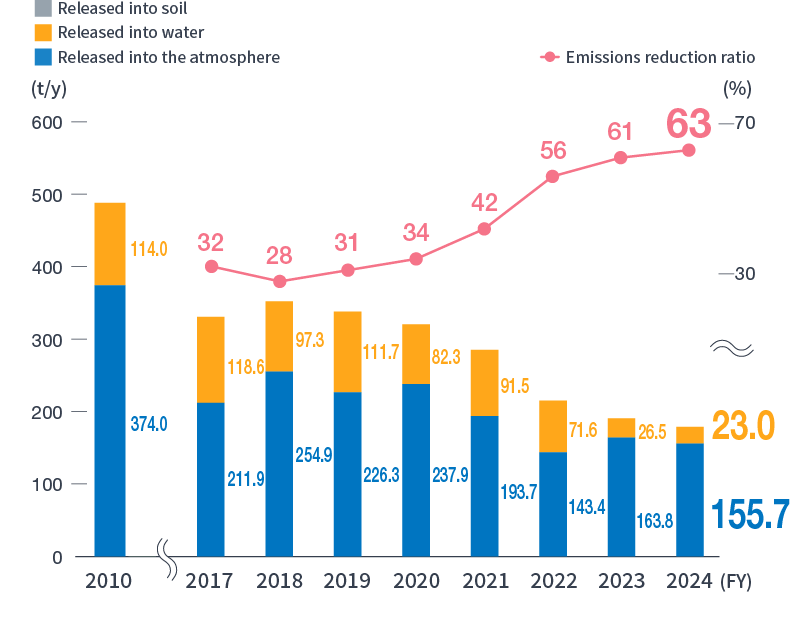

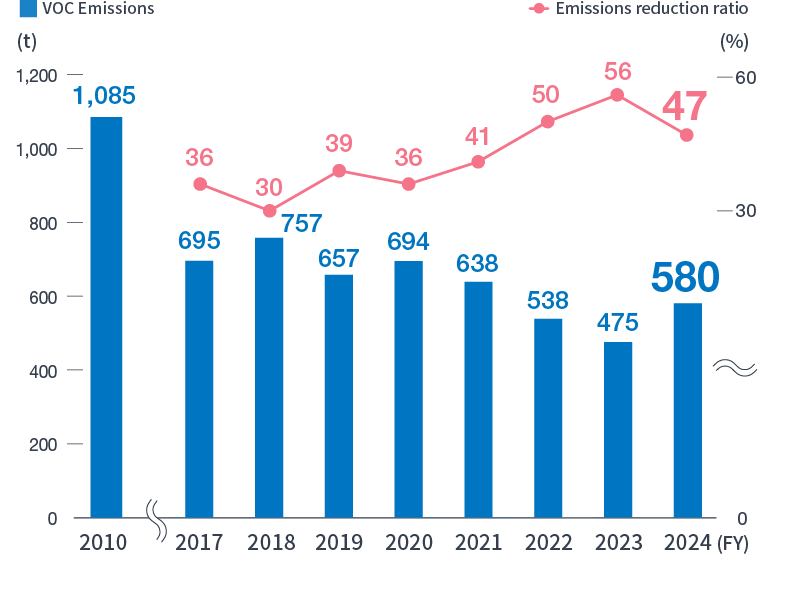

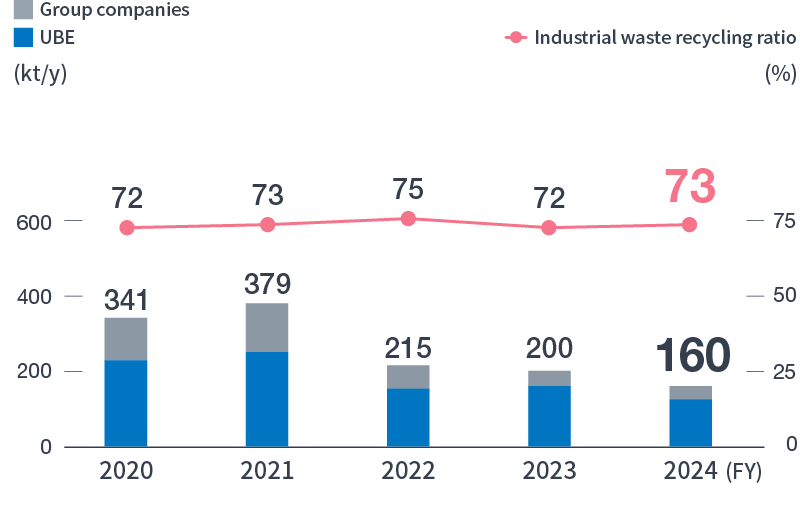

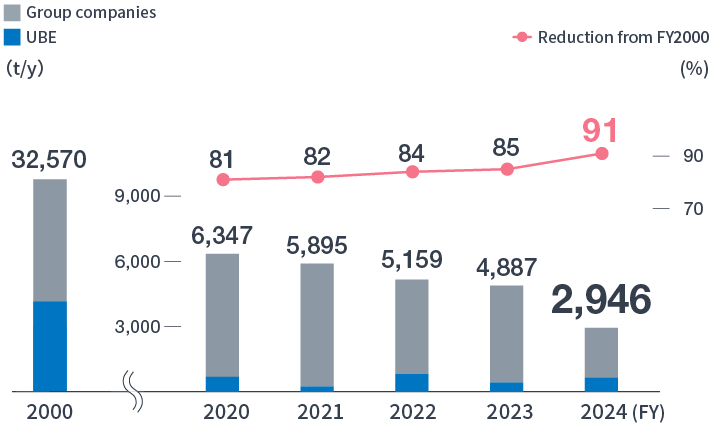

- We will continuously monitor the emissions of pollutants (air pollution, water pollution, soil pollution, etc.) generated in our operations and strive to control emissions.

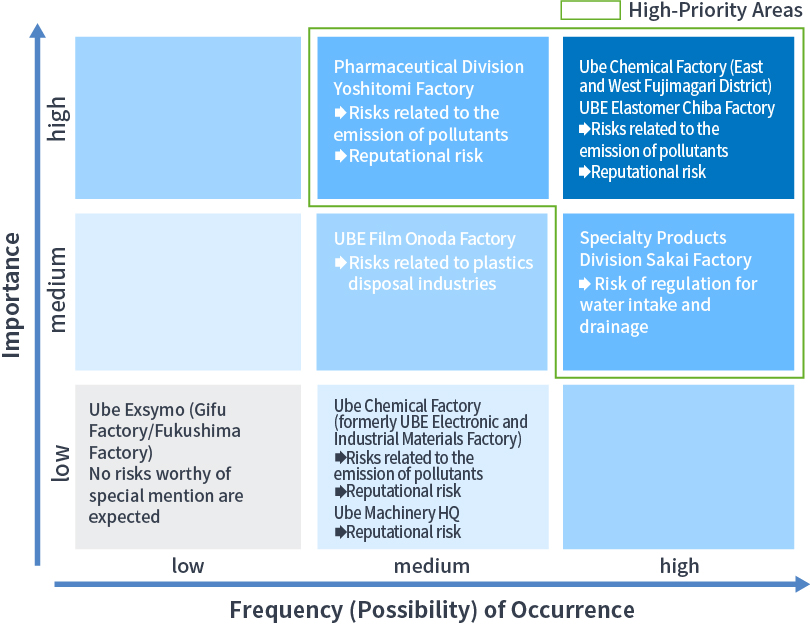

- We will identify and assess water risks at our main business sites and strive to conserve and effectively utilize water resources that are important to our business.

- In order to reduce the environmental impact of the entire supply chain, we will engage with stakeholders.

- We will fulfill our commitment to Carbon Neutrality and the realization of Circular Economy.

- We will continue to engage with suppliers who account for the top 50% or more of the raw material procurement volume and will further enhance the scope engagement in the future.

Responsible Departments and Review

The Sustainability Department is responsible for overseeing and managing this policy.

This Policy is subject to regular review at least once every year. Any revisions, whether as part of a scheduled review or required during the fiscal year, will be deliberated and approved by the Environmental Issues Committee.

- Contributing to the Conservation of the Natural Environment (Nature Positive) (PDF: 531KB)

- Guidelines on Contributing to the Conservation and Restoration of the Natural Environment (Nature Positive) (PDF: 2.34 MB)

- *Materials on the UBE Group’s basic mindset and the status of activities related to contributing to the conservation and restoration of the natural environment (nature positive)