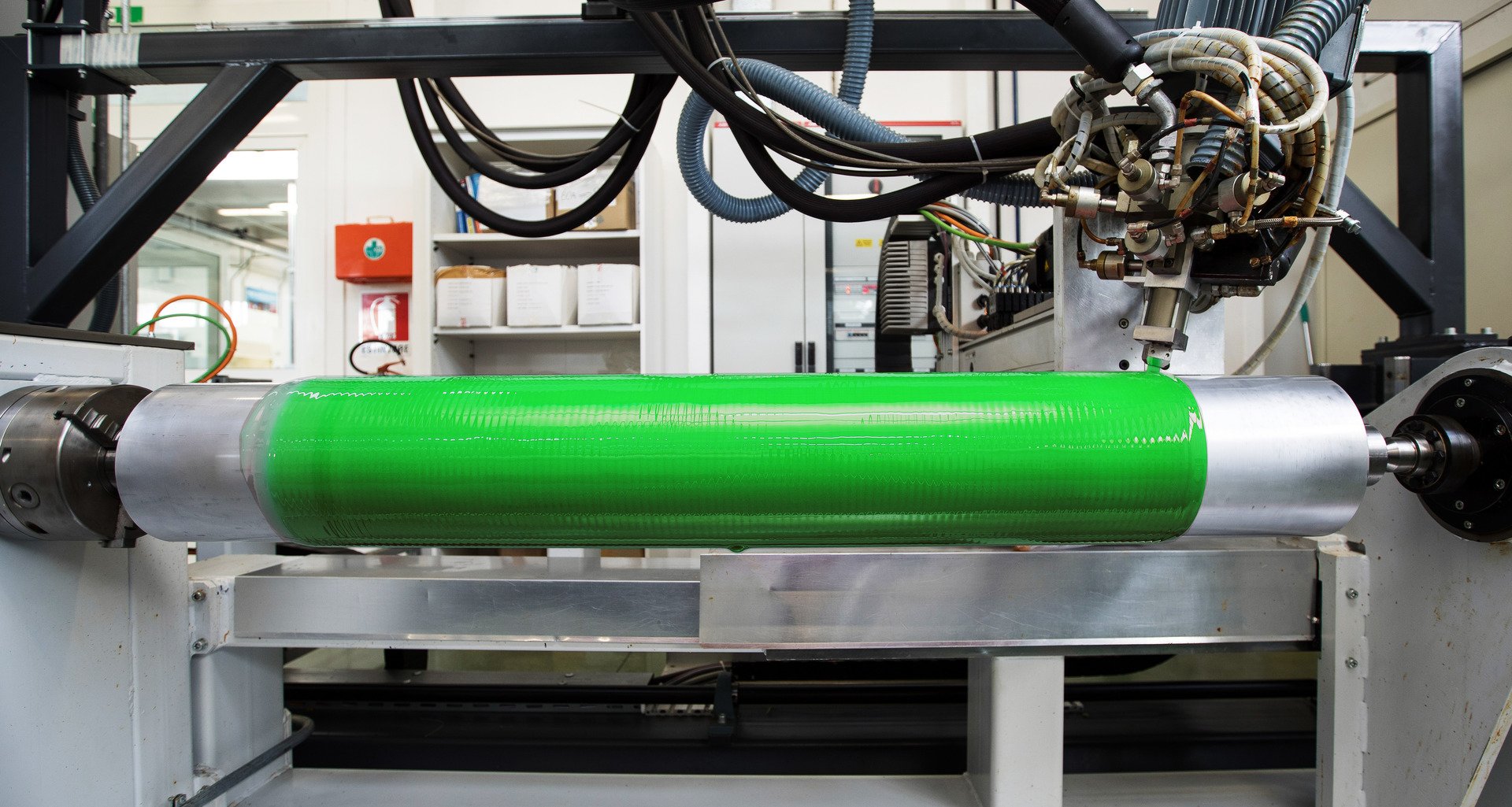

Adiprene® LF MDI systems for excellent performance and easy processing. To pour parts with outstanding dynamic performance, excellent retention of properties, and high load-bearing capabilities.

For excellent performance and easy processing

Adiprene® LF MDI prepolymers provide significant health and safety advantages due to low free isocyanate levels and the ability to cure with diols, in addition to a range of other suitable curatives. This ground-breaking innovation enables customers to pour parts with outstanding dynamic performance, excellent retention of properties, and high load bearing capabilities. Adiprene® LF MDI prepolymers demonstrate significant improvement in performance, processing, and industrial hygiene. Complete LF MDI-based urethane systems, including the prepolymer, curative, and catalyst, can be designed with reduced hazard classifications.

Compared to conventional prepolymers, the benefits of Adiprene® LF MDI prepolymers include:

- Reduced free MDI levels (<0.1%) greatly improve workplace safety

- Lower viscosity for easier mixing and pouring

- Longer pour life, enabling the casting of very large and complex parts

- Catalysts to achieve very high productivity

- Processing using either hand batching or meter-mix machines

- Faster demolding improves productivity and reduces costs

Adiprene® LF MDI elastomers offer outstanding dynamic performance with lower hysteretic heat build-up that extends product life, in combination with excellent retention of modulus at high temperature, and high load bearing capabilities.

Adiprene® LF MDI prepolymers are available with a wide range of polyol backbones. UBE Urethane Systems scientists can work with you to customize a special formulation to achieve your ideal performance.