Polyimide NEWS

AABC Europe 2025 appendix data: Applicability of

Water Solvent Polyimide Binder for Si-system anode

2025/6/24

2025/6/24

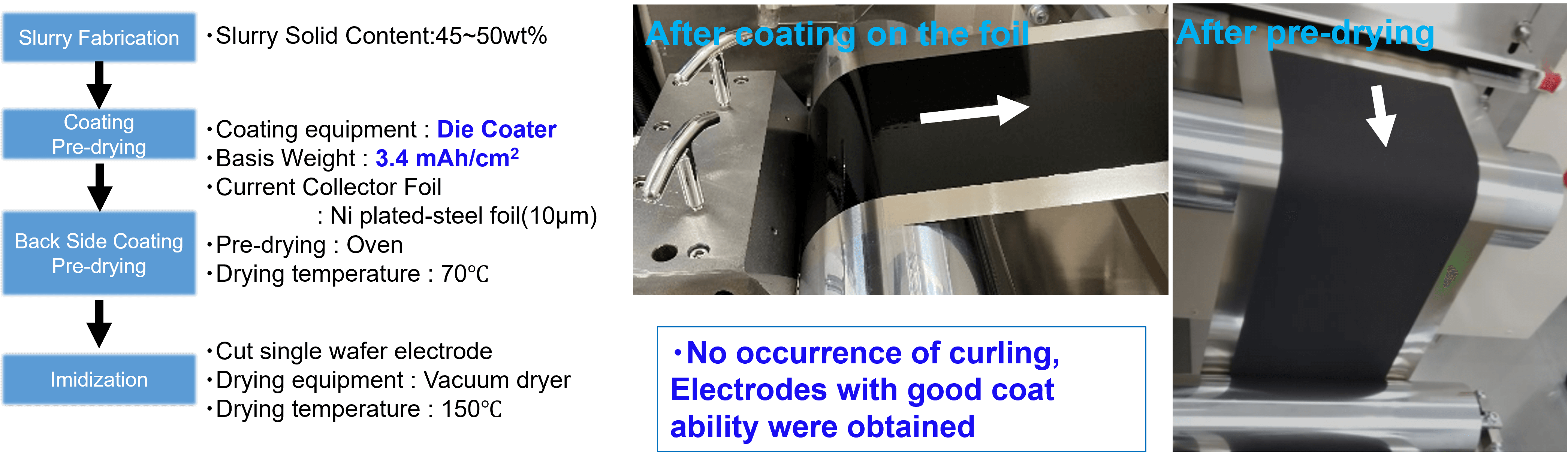

Serial Coating Trial and Charge-Discharge Evaluation of

SiO Electrodes Using Newly Developed Polyimide Binder

In roll-to-roll coating electrode, no occurrence of curling and electrodes with good coat ability were obtained.

Composition of SiO anode

| SiO (1400mAh/g) wt% |

Binder wt% |

AB wt% |

MWCNT wt% |

SWCNT wt% |

Basis Weight mAh/㎠ |

|---|---|---|---|---|---|

| 78.0 | 7.0 | 14.7 | 0.2 | 0.1 | 3.4 |

How to make Anode

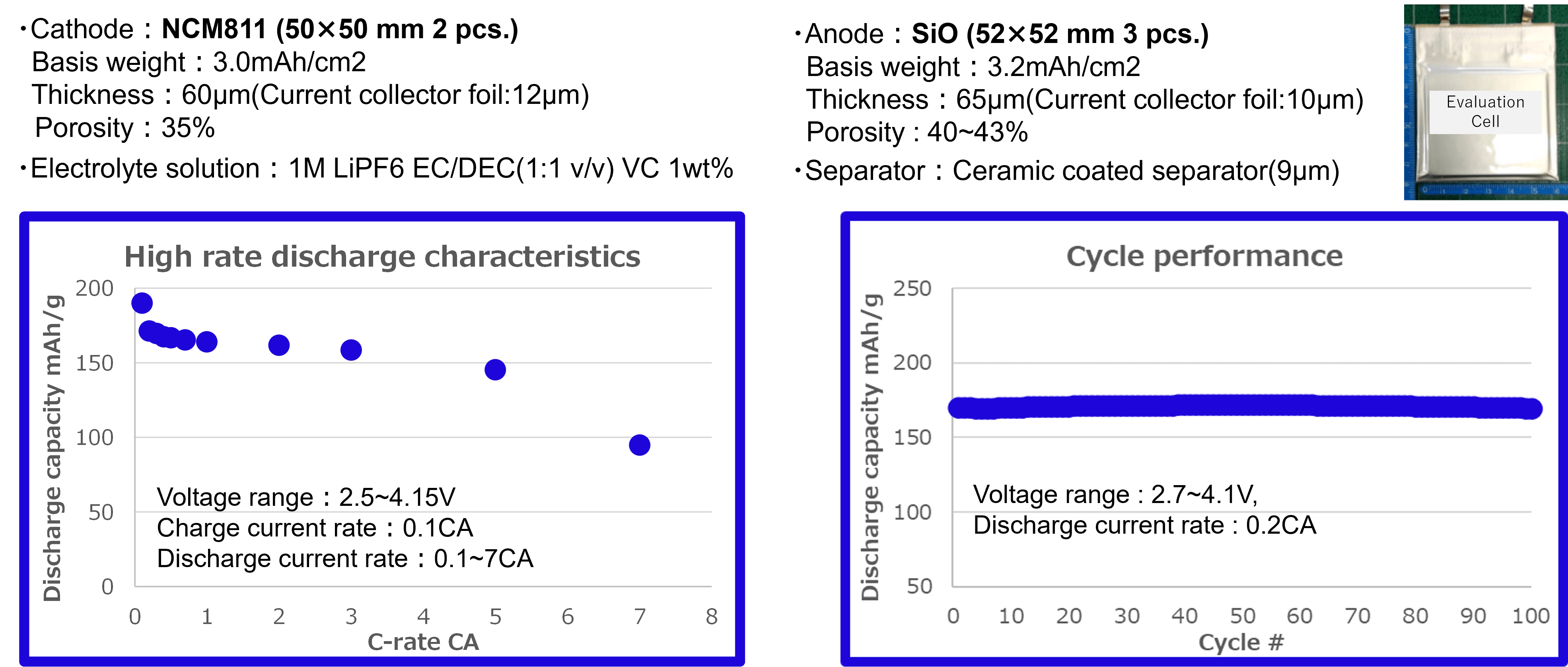

Evaluation of 300mAh class cells using prototype electrodes

Heat treat roll-to-roll coating electrode at 150°C. Laminated cell is shown excellent high-rate discharge characteristics and cycle performance.

・Design of 300mAh laminated cell

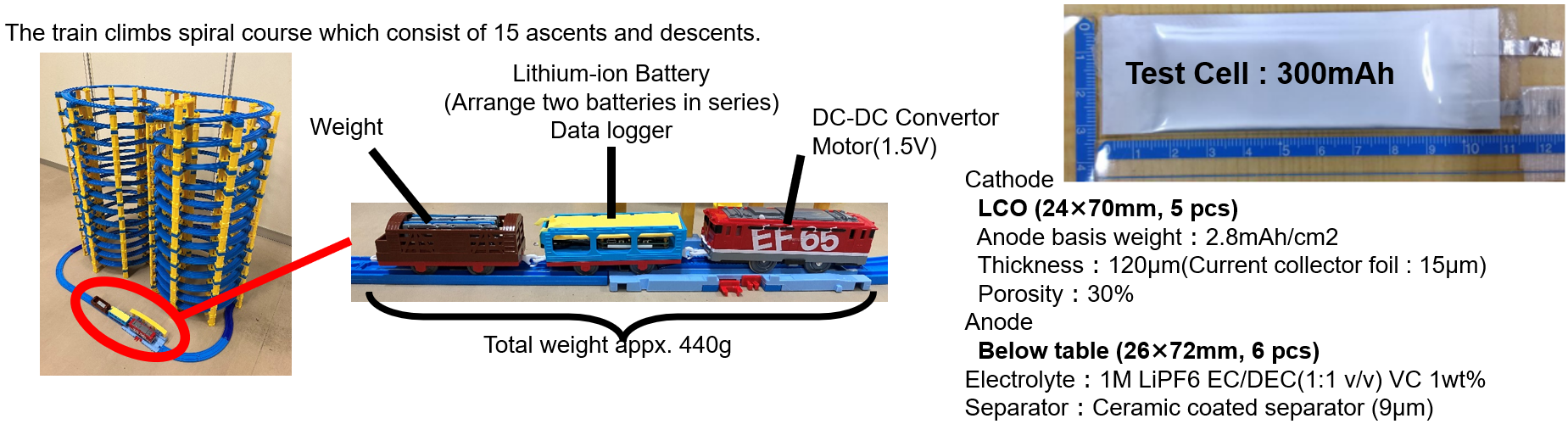

Application demonstration using prototype electrodes

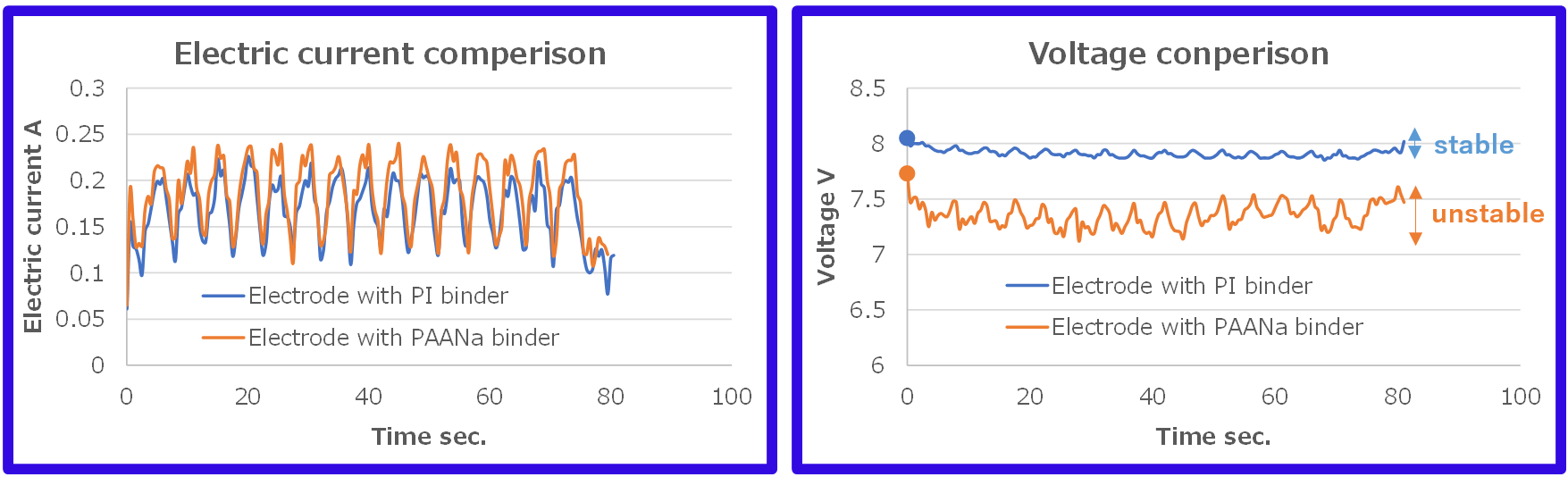

Implemented verification of roll-to-roll electrode performance applying electric toy. Visualize both voltage and current on working the application and find out advantage of newly polyimide binder.

Application:Plarail® ,which is electric train toy.

Cathode (Compared at SOC 100 after aging.)

| Binder | SiO wt% |

Binder wt% |

AB wt% |

MWCNT wt% |

SWCNT wt% |

Basis Weight mAh/㎠ |

Thickness µm |

|---|---|---|---|---|---|---|---|

| ① Water based PI |

78.0 | 7.0 | 14.7 | 0.2 | 0.1 | 3.2 | 68 |

| ② PAANa |

78.0 | 7.0 | 14.5 | 0.4 | 0.1 | 3.2 | 70 |

Left:Polyimide Binder Right:PAANa Binder

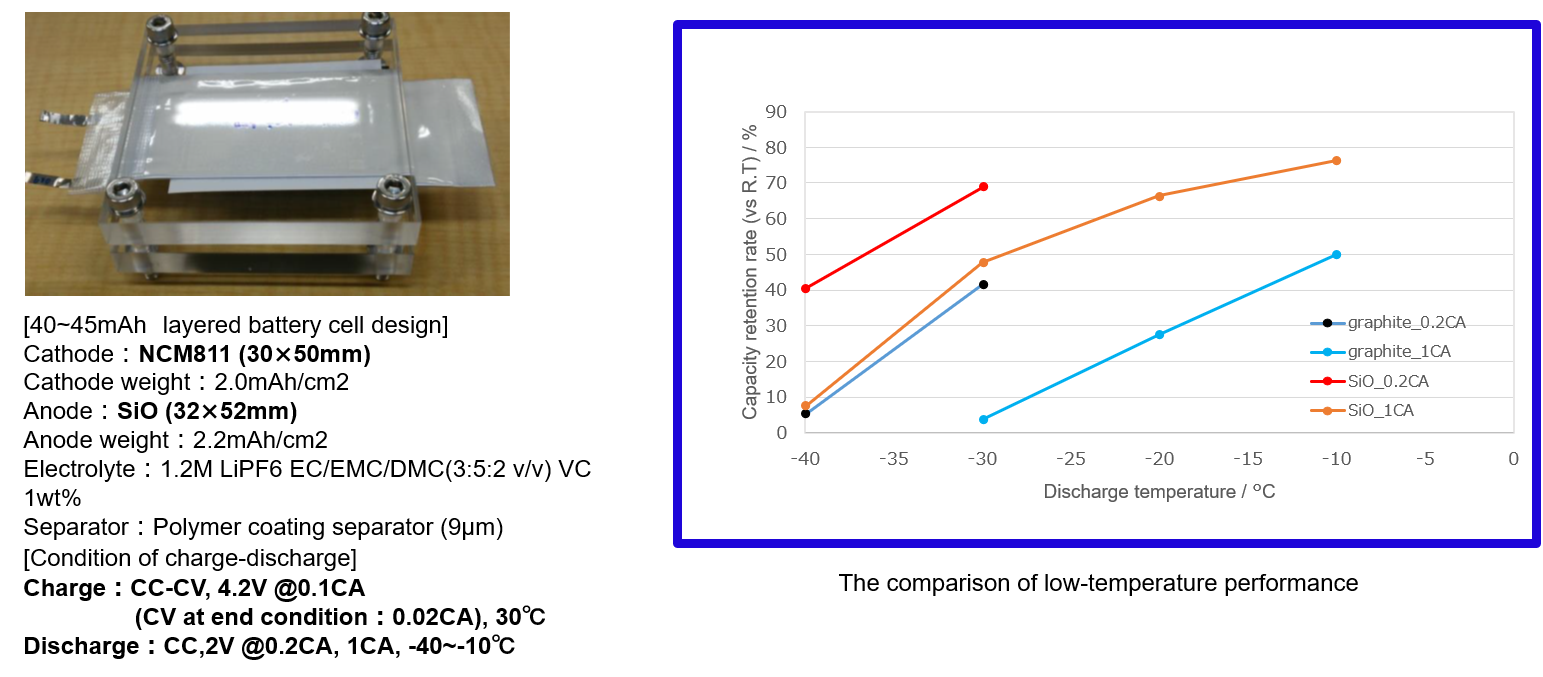

Evaluation of SiO electrode using U-Varnish-18D018:

Low-temperature performance

The composition of SiO and PI binder have confirmed for working well at -40 Celsius degree, 0.2CA. Graphite electrode which is using SBR-CMC could not work at low temperature.